Offset / Flexographic Printing

Improving the Productivity of Offset Printers

For Over 40 Years

Since 1970, Hadronics has been offering engineering, manufacturing and repair services to both offset press manufacturers and printers throughout the world. Whether it is a sheet-fed or web-fed process, our comprehensive selection of hard-coatings for all types of rollers and our full-service machine shop position us to take care of all your print roller needs. If you are printing books, periodicals, brochures, packaging for consumer goods or some other application, Hadronics’ precise work, quick turnaround and total quality control will help keep you running faster and more efficiently.

Case Studies

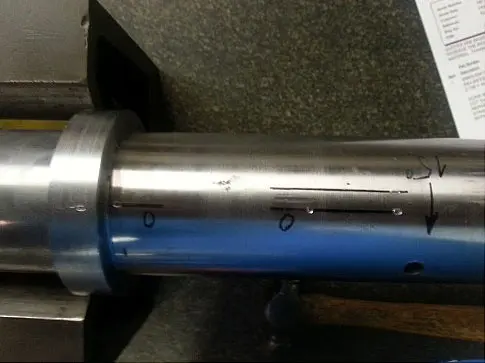

Press Down Due to Separated Infeed Shaft

Challenge: When our customer (a large commercial lithographer in the Midwest) contacted Hadronics, they were in a very tough situation. On one of their presses, the infeed shaft had separated from the body on the gear side of the press, which produced a crack in the weld. When the manufacturer was contacted, our customer was told that the lead time to get a spare shaft would be 4 to 6 weeks because the shaft was not a highly used spare part, so it was not kept in stock. Therefore, a new shaft would have to be manufactured and shipped from Germany. This was not acceptable, so Hadronics was contacted.

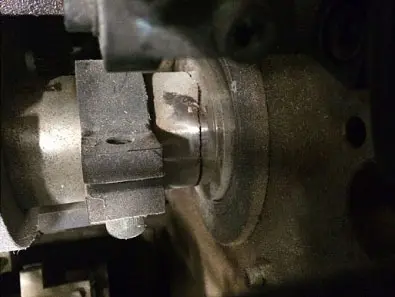

Solution: Hadronics received the call and responded immediately. We worked closely with the mechanic to find out more about the situation and how the problem occurred. After considering a number of alternatives, we were able to rotate the body to the degree needed for the mating parts to reassemble. This enabled us to get the press running in approximately three days.

Infeed shaft assembled in press

Constant Innovation in the World of Flexography

Hadronics draws on over 40 years of experience in flexography to help both press manufacturers and printers to improve the productivity of their operations through constant innovation. Whether you print corrugated boxes, flexible packaging, bags and sacks, beverage cartons, flexible plastics, self-adhesive labels, disposable cups and containers, envelopes or wallpaper, Hadronics can help you improve your processes. Our extensive selection of coatings and sprays, full machining capabilities and years of experience allow us to repair or rebuild your flexographic rollers quickly and cost effectively. Hadronics has experience helping you improve your process to make your operational window wider with water- and oil-based based inks and printing on a variety of different materials including plastic, foil, acetate film, brown paper, and other materials used in packaging. Printing press speeds of up to 600 meters per minute (2000 feet per minute) are achievable now with modern technology high-end printers and we can help ensure your rollers function optimally in this environment.